Dust

Home » Dust

Dust

LEAK LOCATE 320 Plus

- Probe control option (insulator short-circuit check) for improved data integrity

- Digital display and optional graphical display for real-time data viewing and monitoring of bag cleaning cycles

- Reduces filter maintenance frequency, process downtime, and filter costs

LeakAlert75

- Reliable monitoring of leaks and bag failures in dust collectors

- Built-in drift control sensors (zeroing and calibration)

- Probe check option for improved data integrity

QAL 260

- MCERTS QAL1 approved, standalone or multi-sensor CEM for particulate measurement, ensuring high-quality emission monitoring at low dust concentrations from dry industrial processes.

- ProScatter™ Backscatter sensor technology with improved minimum detection <1 mg/m³

- Certified up to 15 mg/m³ for processes with low typical emission limits

- Exhaust gas lock option protecting plant engineers from harmful exhaust gases during maintenance

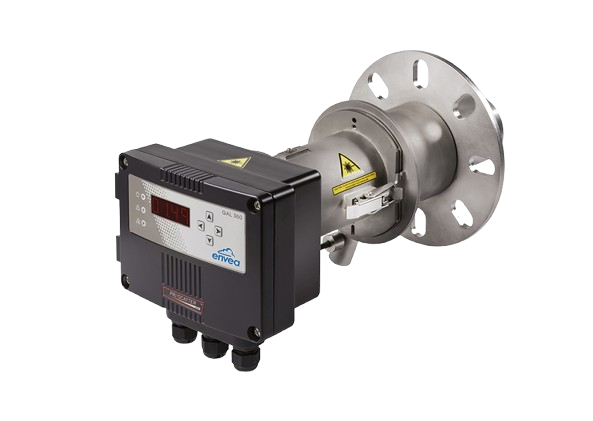

QAL 360

- ProScatter™ Backscatter sensor technology with improved minimum detection <1 mg/m³

- Certified up to 7.5 mg/m³

- Automatic contamination control – full optical system check

- Used at low or high dust levels, meeting the stringent minimum emission limit value of 5 mg/m³ for large combustion plants as specified in the Industrial Emissions Directive

QAL 991

- QAL1 certified according to EN 15267-3, approved under both MCERTS and TUV.

- Compliant with EN 13284-2, EN 14181, and EN 15267-3 standards, suitable for applications with emission limit values (ELV) of 7.5 mg/m³ (combustion) and 15 mg/m³ (co-combustion).

- Easy maintenance, no need for specialized service personnel

QAL181

- QAL1 certified ranges: 0 – 7.5 mg/m³, 0 – 15 mg/m³, 0 – 100 mg/m³, 0 – 200 mg/m³, covering 0 – 7.5 mg/m³, the lowest achievable for any PM-CEM (Continuous Emissions Monitor for Particulate Matter).

- Designed for use in high-temperature stack conditions and explosive hazard zones

- ProScatter™ technology provides enhanced measurement with reduced cross-sensitivity to particle type and size

- Easy auditability with manual filters

QAL182WS

- Extractive sampling system configurable for constant velocity or variable flow isokinetic sampling.

- Meets QAL1 certification requirements and other international standards

- Easy to operate, intuitive multilingual menu with a large display for improved user interaction, featuring onboard diagnostics and multiplexed analog and digital outputs.

- Small sampling chamber and advanced polymer application – prevents particle adhesion, condensation, and crystal formation. Reduced maintenance requirements for the end user.